Electric Motorized Actuated Shut off and Regulating Needle Valves

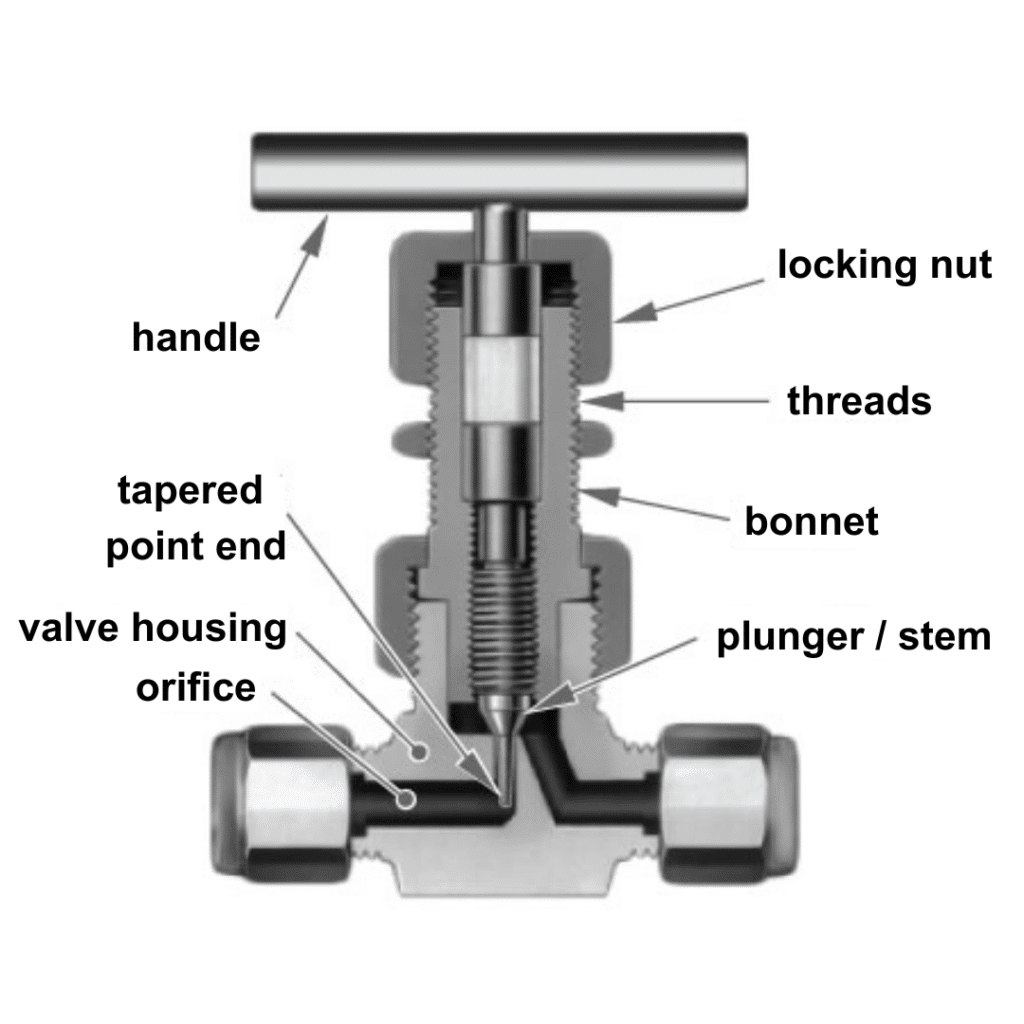

Needle valves give you the ability to manage that flow as closely as you need to due to the specialized shape of their plunger. Gradual adjustments of the stem and plunger enable smooth flow control. It can also handle high pressure.

How do they work.

When you turn the handle of a needle valve, it raises and lowers a tapered plunger to open or seal the valve. The plunger moves up and down on threads inside the shaft of the valve, and there’s a locking nut to prevent it from unscrewing all the way out.

Because the plunger moves up and down on threads, you can very accurately control where the tapered end of the plunger sits in relation to the valve seat. This allows you to control flow very precisely between maximum and zero.

In Motorized Version, it is precisely moved with the help of motors and position feedback controls to achieve the desired output parameters.

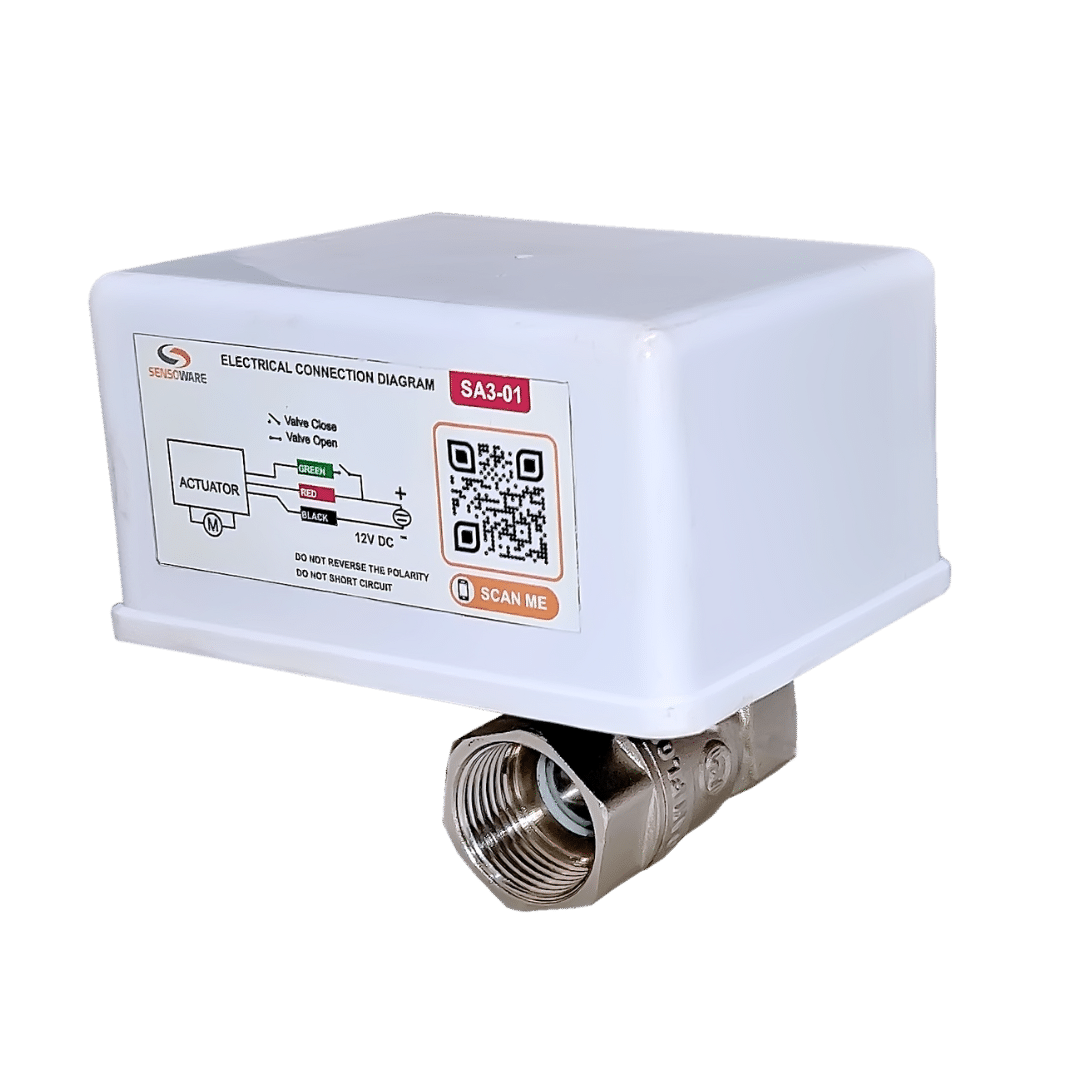

Electric Motorized Actuated Shut off and Regulating Needle Valves – 15mm / 1/2 inch

Motorized Needle Valve can be used for High Temperature or High Pressure handling. It is used for precise flow control. It is available in various voltage options like 12V DC, 24V DC or 220V AC. Our Automatic Needle Valves are available in ON/OFF or Regulation / Modulating type.

Specifications

| Size | 15mm / 1/2 Inch screwed ends |

| Material | SS304 / SS316 |

| Voltage | 12VDC / 24VDC / 220VAC |

| Function | ON/OFF or Modulating |

| Feedback | Optional |

| Operating Speed | 30 – 60 Seconds |

| Temperature | upto 90°C |

| Pressure Rating | upto 1500 Bar |

| Number of Ports | 2 Way |

| Video | https://youtu.be/rEL-UxPWmpY |

Frequently Asked Questions

Browse Related Products

See in Action!

Follow our Social Channels